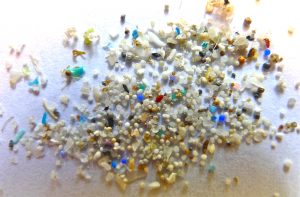

Microplastics are frequently being found by researchers, but they are not identified as oxo-biodegradable.

It has recently been estimated that the amount of plastic in the oceans has reached 20 million tons, making up to 80% of marine anthropogenic debris.

In the 1970s, Professor Gerald Scott and other polymer scientists who had themselves invented and developed plastics realised that polyethylene and polypropylene could cause a serious environmental problem if it escaped from the waste management process and ended up in the open environment as litter.

I had the privilege of knowing Professor Scott.

He told me that, anticipating that much of the plastic litter would not get collected, they decided to try to solve the problem. They discovered that if they introduced into the normal polyethylene or polypropylene a tiny amount of a catalyst (usually a salt of manganese or iron) the plastic would remain serviceable whilst in storage and would perform in exactly the same way as normal plastic whilst in use, but if discarded into the open environment it would rapidly become biodegradable, and be consumed by bacteria in the same way as nature’s wastes. Why biodegradable?

They called it oxo-biodegradable, because it degrades first by oxidation and then when its molecular weight has been reduced to 5,000 Daltons or thereabouts it has ceased to be a plastic and is consumed by the bacteria, leaving no microplastics or toxicity. Unlike the type of plastic marketed as compostable, it does not need special conditions, and will degrade and biodegrade anywhere in the presence of oxygen and bacteria.

Prof. Scott published his work in many peer-reviewed publications including “Polymers & the Environment” (ISBN 9780854045785); “Degradable Polymers; Principles & Applications” (ISBN 1-4020-0790-6); and “Programmed-Life Plastics from Polyolefins: A New Look at Sustainability” Scot Wiles

Polymer scientists have continued to research and develop this discovery, and one of Prof. Scott’s colleagues, Radu Baciu, is now Director of Technical at Symphony Environmental. He has been working on this technology for 38 years and is acknowledged to be one of the world’s leading experts in the field.

The most recent research is a four-year study sponsored by the French government, known as the Oxomar project, to evaluate the biodegradation of oxo-biodegradable plastic in marine waters. In their conclusion the French scientists reported that “We have obtained congruent results from our multidisciplinary approach that clearly show that these plastics biodegrade in seawater and do so with a significantly higher efficiency than conventional plastics. The oxidation level obtained due to the d2w prodegradant catalyst was found to be of crucial importance in the degradation process.” See Marine Environment

Prof. Scott said just before he died in 2013 that if oxo-biodegradable technology had been more widely used, the ocean garbage patches would be very much smaller, and polyethylene and polypropylene would not be accumulating in the environment. So why has it not been more widely used? I have been concerned with this since I left the Environment Select Committee in the British Parliament in 1997, and I think I know why.

It was unfortunate that when oxo-biodegradable plastic became commercially available, the public imagination had been caught by the idea of making plastic from vegetable materials. This was not actually a good idea, but was being promoted by some very large companies, and they thought that oxo-biodegradable plastic was a threat to their market share. They therefore embarked on a massive campaign of disinformation and political lobbying against oxo-biodegradable technology all over the world.

The directors of these companies did not want to be seen to be engaged in this anti-competitive behaviour themselves, so they employed skillful lobbyists and trade associations, and they financed environmental foundations and NGOs and academics. They also persuaded some of the recyclers to reject the technology for no good reason. (See Recycling ) They even persuaded the EU Parliament to ban oxo-degradable plastic (which does create microplastics) in such a way as to confuse people into thinking that the ban applies to oxo-biodegradable plastic (which does not create microplastics).

The problem with their vegetable-based product has always been that it does not deal with the problem of plastic in the environment, because it has to be collected first and taken to a composting facility, where it will biodegrade in the special conditions found there. They also deceptively market it as compostable, in the full knowledge that even in a composting facility it does not create compost – it converts into CO2 gas or methane. (See Composting )

The result of their campaign has been a disaster for the environment, because since 1997 many millions of tonnes of plastic which should have been oxo-biodegradable have escaped on land and into the oceans where it will fragment and accumulate for many decades before it eventually biodegrades. This is still continuing, and is getting worse.

With regard to the oil and plastics industries, they knew that people were seriously concerned that their plastic products could lie or float around for decades, but instead of adopting oxo-biodegradable technology they tried to persuade the public that recycling would solve the problem – which of course it has not. I noted in this column on 9th May 2022 that the Attorney General of California had said “recent reporting has uncovered internal documents from the 1970s warning industry executives that recycling was infeasible and that there was serious doubt that plastic recycling can ever be made viable on an economic basis. Indeed, despite the industry’s decades-long recycling campaign, plastic pollution is as pervasive and as harmful as ever.”

Also, anti-plastic campaigning has become a profitable industry for “not-for-profit” organisations who pay their senior staff large salaries, and they have an incentive to oppose a technology which would alleviate the problem without banning plastic. They cannot of course admit that, so they try to attack oxo-biodegradable technology on technical grounds. They are currently lobbying the Senate of Brazil, and if they succeed it will be a disaster for Brazil’s environment.

Almost every month my attention is drawn to an academic paper which is being used by lobbyists against oxo-biodegradable technology, but when I study them, with the help of Radu Baciu, I find them misleading. For example, one claimed that an oxo-biodegradable mulch film showed very slow degradation, but the material used for the tests had been heavily over-stabilised. Another failed to ascertain that the test material was oxo-biodegradable at all. In a third paper, the test material might have been correctly made with a suitable masterbatch or it might not. This deficiency was enough to invalidate the whole paper, but they then proceeded to expose the sample to abiotic degradation for a period which was much too short. The fourth actually proved that abiotic oxidation helps to reduce the molecular weight of oxo-biodegradable polyethylene and form easily biodegradable fractions.

One line of attack has always been to allege that oxo-biodegradable plastic creates microplastics, well knowing that most of the microplastics are created by fragmentation of ordinary plastics when exposed to sunlight, and being aware that after studying oxo-biodegradable plastic extensively in 2017/18 the European Chemicals Agency were not convinced that it formed microplastics. Microplastics are frequently being found by researchers, but they are not identified as oxo-biodegradable.

It is also said that oxo-biodegradable plastic does not biodegrade fast enough, but the key point is that it biodegrades very much faster than ordinary plastic in the same place anywhere in the open environment. Queen Mary University have estimated 90 times faster. https://www.biodeg.org/wp-content/uploads/2022/10/QM-published-report-11.2.20-1.pdf The plastic product needs to have a reasonable service-life, and as it is not intended for composting it does not need to biodegrade according to the short timescales required by the industrial composters, specified in Standards such as EN13432 and ASTM D6400.

Another misfortune was that, not knowing that it was possible to make plastic litter biodegrade, a well-meaning group of activists started campaigning against the plastic supermarket carry-bag, which could and should have been made with oxo-biodegradable technology. The supermarkets were happy about this, and may even have encouraged it, because it was costing them money to provide free checkout bags. What they now do is to make the customer pay for a thick plastic bag – or a paper bag, both of which are worse for the environment. (See Paper Bags ; Denkstatt report ; LCA ) Today all the short life plastic used and sold by supermarkets ought to be oxo-biodegradable, because they have no way of knowing whether it will be disposed of responsibly.

All of this is a sorry story, but people around the world are now realising that “reduce, re-use, recycle” is not going to solve the problem, and that oxo-biodegradable technology is the only way to prevent the accumulation of plastic products and plastic fragments in the open environment. Some countries in the Middle East have already made it compulsory to use this technology.

LegalReader thanks Michael Stephen for permission to republish this article. The original is found here.

Join the conversation!